Infrared technologies, whether PAS or NDIR, are a great option for DGA monitoring. Infrared also makes it possible to create a maintenance-free DGA monitor that does not need any recalibration — if you can solve the challenge of oil aging.

Dealing with and managing aging oils

IR gas detection is a fundamental method that relies on simple physics. Each gas has a certain IR wavelength which they absorb, and this principle is used to both identify the gases and measure their concentrations.

On the other hand, transformer oils in service are surprisingly complex in their chemical compositions. To make the situation even more challenging oils age over time due to oxidation, thermal stress, etc.

This leads to new compounds being formed — hydrocarbons, which sometimes are evaporative and have the same absorption wavelengths as the fault gases. And that's exactly the problem: overlaps in IR absorption. When the new compounds interfere with the fault gases being analyzed it leads to errors in DGA results.

You could of course recalibrate your DGA monitor, but that would mean taking it offline, with resultant costs and loss of productivity.

It's exactly why we asked ourselves if we could eliminate the effect of gas interference without resorting to costly recalibration.

How can you tackle aging oils in an IR-based DGA monitor?

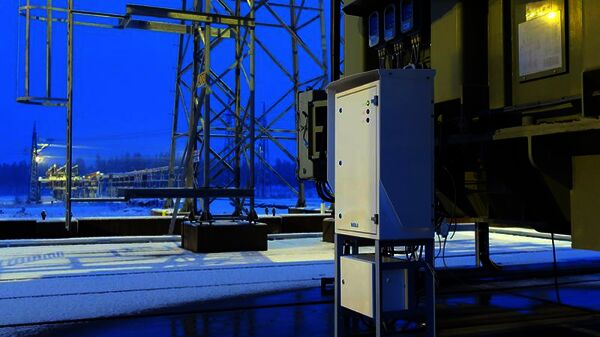

Vaisala's Optimus™ OPT100 online DGA monitors incorporate a unique method, simply called Autocalibration. The monitor frequently and automatically analyzes the oil composition, and compensates for interfering gases — entirely eliminating the need for recalibration.

This is one of the features that confirms the long-term stability and maintenance-free operation of the Vaisala Optimus™ OPT100 online DGA monitor.