High-humidity environments are tough for humidity measurement. Saturation in the environment causes condensation to form on all surfaces including measurement sensors, which can be fatal for some technologies. While Vaisala HUMICAP® technology can withstand condensation, it still needs time to recover from the effects of moisture before it can once again provide reliable measurements. Typical applications where high humidity or occasional condensing are expected include drying processes, test chambers, combustion air humidifiers, meteorological measurements, and fuel cells.

Keeping measurements accurate and reliable even in condensing environments calls for Vaisala’s probe warming technology. A warmed probe keeps the sensor continuously above the ambient temperature, ensuring condensation never forms. The disadvantage of probe heating is that relative humidity can no longer be measured because the sensor won’t know the ambient temperature. However, this doesn’t prevent other temperature-independent parameters from being measured, such as dew point or mixing ratio. It is also possible to measure relative humidity using an additional temperature sensor.

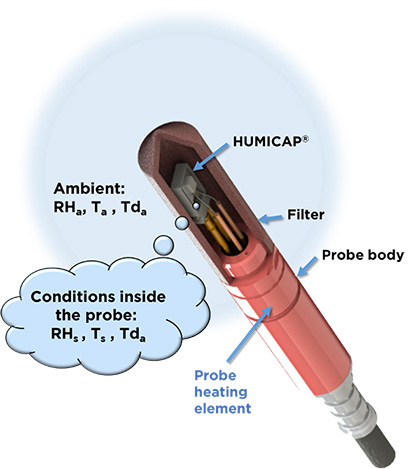

Operating principle

The heating element inside the probe body heats the entire probe. In this illustration, the probe and filter are glowing red to illustrate how the probe warming keeps the microclimate inside the filter at an elevated temperature. The actual temperature is only a few degrees above the ambient temperature, as seen in the example below:

As shown in this example above, heating does not affect dew point. If relative humidity or another temperature-related parameter is needed, then the ambient temperature can be measured with a separate temperature probe, allowing these parameters to be calculated as well.

Insulation and leak-proof process connections

Choosing where to install a humidity probe can be challenging when there is high humidity combined with temperature variation. For example, in a drying application where the exhaust air humidity is close to saturation (RH 95%) and the temperature is 40 °C, what happens when the sensor head is installed so that the filter is in the process and half of the sensor is in the 25 °C ambient temperature? In this situation even probe warming may not be able to compensate for the heat loss caused by thermal conduction through the metallic probe body; the heat loss will form a cold spot on the process side and condensation will result in inaccurate measurement. The solution here is to thoroughly insulate the probe.

If the process gas is colder than the ambient air it is critical to have a tight process connection for the probe. A leaking connection will allow warm and possibly humid air into the system, which can condensate near the sensor and cause measurement problems.

Extreme conditions, such as PEM fuel cell applications

There are also extreme applications where warming just a few degrees above the ambient temperature is just not enough. One example of such application is a Polymer Electrode Membrane (PEM) Fuel cell. Application-specific configurations can be found in the order forms of HMT330- and HMT310-series. These configuration versions are designed to withstand the extreme conditions by heating the probe head at a higher power. It is also possible to use HMP7 and HMM170 in these applications, since the heating functionalities are freely configurable with the Insight PC software.

Summary

Sensor saturation can be avoided in high-humidity and condensing conditions by using an instrument that has probe warming technology. In addition to this, proper insulation and leak-free installation guarantees the best possible environment for reliable humidity measurement.